SERVICES, EQUIPMENT, AND TECHNOLOGY

Our use of state-of-the-art equipment and experienced technicians are differentiators for S&S, leading to our customer’s confidence and long-term partnerships. Setting the highest-quality standards for the steel fabrication industry, we consistently reinvest in our plant and employees; benefiting you, the client. Our experienced technicians operate the latest in fabrication equipment housed in our modern 100,000 square foot manufacturing facility, utilizing steel from six different suppliers. As a company, we’re armed with the latest in cutting-edge technology and the most advanced equipment in the industry. This allows S&S Welding to provide our clients with the finest in premium steel fabrication.

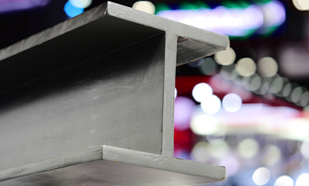

Structural Steel Fabrication

We have multiple steel suppliers to manage costs and ensure our clients are getting the highest quality product at the best value. We purchase raw material based on specific client requirements. Purchased steel is then fabricated to precise customer specifications using detailed digitized plans/files that encompass cutting, welding, painting, etc. for the specific project. We use the latest in BIM modeling for detailing to optimize, fabricate, and provide the highest precision with low error rates.

- Bending/Forming

- Cambering

- Column, Beam Shapes, Parts

- Embeds

- Plasma Cutting

- Plate & Structural Steel

- Shearing

- Miscellaneous Steel

- Bollards

- Dumpster Gates

- Ladders

- Railings

- Stairs

Structural Steel Erection

We recognize the importance of experience, knowledge, and safety. That being said, we outsource to the best field crews in the industry to ensure fast deployment and fewer jobsite delays.

Additional Services

S&S Welding serves as a nationwide supplier of materials and is licensed in Alabama dba Stacks, Inc. (#S-68656); Arkansas (#0387710524); Florida (#CGC1516661); Louisiana (#66515); Tennessee (#76655).

Equipment

Structures are only as good as the equipment with which they’re built. That’s why S&S Welding uses only state-of-the-art, paramount equipment that’s not only reliable, but offers the latest in fabrication technology, providing our technicians with the ability to achieve high quality results, low error rates, and a safer work environment.

Our latest acquisitions include:

PeddiAssembler – The PeddiAssembler, powered by Zeman, is the absolute solution for steel beam assembly. This fabrication shop supercharger has been designed specifically to speed up one of the most time-consuming areas of the fabrication process.

(3) PythonX Structural Fabrication System – The #1 Robotic Structural Fabrication System in the world. This complex solution automates processing operations while providing increased productivity and unmatched cut quality with predictable and consistent output.

Zeman SPS (Steel Parts Sorter) – The SPS provides quality assurance through plate digitization and tracking, as well as optional storage.

PeddiBlast-1500 – The PeddiBlast shot blasting system utilizes the most sophisticated and robust shot blasting technology for structural steel.

(2) Meeser Metalmaster Xcel plasma tables – The MetalMaster Xcel features state-of-the-art industry leading traversing speeds of 3000 IPM, robust design, and high acceleration drives. Features include a 10’X20’ slagger table, a Global Rotator Delta bevel that can cut up to 52 degrees and 460 degrees rotation, cut and piercing up to 2” thick, with edge cuts up to 3” thick, overall accuracy of +/- .002 at travel speeds up to 3,000” per minute, pin stamp marking, and Hypotherm HPR4000XD.

Straddle Carrier by Combilift – The Combi-SC range is the most economical handling solution for heavy and oversized loads. Its maneuverability, light footprint and high customization offer complete independence when moving containers and oversized loads.

Accurpress 400 Ton x 14’ – This machine features rugged builds, oversized components, and powerful gauging devices. It is tough, durable, and stands up to any forming challenge.

Accurshear 3/8”x12’ – This North American-built machine is a combination of simplicity and strong, proven design. This heavy-duty shear can tackle any application.

Hydmech M20A – An automatic horizontal pivot band saw providing exceptional miter cutting capability for heavy-duty applications. It provides exceptional cutting performance on a wide range of material.

Hydmech M20A-120 – A heavy-duty automatic horizontal pivot band saw with an ability to miter cut from 90 to 60 degrees. It makes an excellent machine for large fabrication jobs.

Cambco 1170 W40x244 Cap – A cambering machine that utilizes two primary hydraulic cylinders spaced some distance apart. This distributes the bending over a length of beam; thus, the strains from the direct pressure on the web and the bending are not concentrated at one spot as is the case when a single ram is used. This, along with special guides and supports, reduces the possibility of twisting and buckling.

120-Ton Ironworker – The Scotchman Ironworker is an American-made hydraulic ironworker designed for metal fabrication. Scotchman Ironworkers are among the best in the business and the most trusted and versatile machine a person can have in their manufacturing or fabrication shop.

Ocean Angle Line Cap. 6x6x5/8” – The world’s most compact angle line with a unique patented design that gives it an edge in the market place where processing clip angles and long bracing angles is a necessity. The ability of it to efficiently process short and long flat bar makes this machine so versatile.

Overhead Cranes – Optimizing productivity, safety, and space savings, overhead cranes allow for easy lifting and moving in industrial facilities. S&S currently operates with seven 5-ton overhead cranes and eight 10-ton cranes.

Technology

We use the most advanced operational software, including Fabtrol, FabSuite, Camduct-Plasma Table, ProNest, Versafab-Python, AutoCAD-Python and Plasma Table, SDS2-TEKLA Detailing System, and P2 Programs-Steel Tracking System.